Services

Sustainable energy generation through the drinking water supply with the synergy renovation of the elevated tank in the Municipality of Hippach in the Zillertal valley:

- Perform a variant study

- Creation of a submission plan with subsequent tendering and awarding of all trades

- Subsidy process including the final approval process

- Concretisation of a feasible execution plan

- Complete technical and commercial construction supervision of the master builder works, plant construction and electronic I&C trades

Facts & Figures

- Company

- AEP Planung und Beratung GmbH

- Completion

- 2020

- Area of expertise

- Water + Environment

- Construction style

- New construction, rehabilitation

- Construction type

- Supply lines

- Work carried out

- Rehabilitation of elevated tanks, installation of drinking water power plants, construction of a comprehensive control system, new construction of power plant pipelines, new construction of a spring collection chamber

- Client

- Municipality of Hippach

Project description

In 2016 and 2017, the water supply system of the Municipality of Hippach in the Zillertal valley underwent several rehabilitation measures from the area near the Hochschwendberg to the Municipality of Waldegg. The water supply system in this area was brought up to the latest state of the art.

In the course of the rehabilitation measures, a drinking water power plant was built in each of the elevated tanks II Grün, III Perler, IV Greider, V Tal and Waldegg. Furthermore, the elevated tank I Aue was rebuilt and partially rehabilitated, and the existing Aue spring water chamber was demolished and a new spring water chamber including a UV system was built.

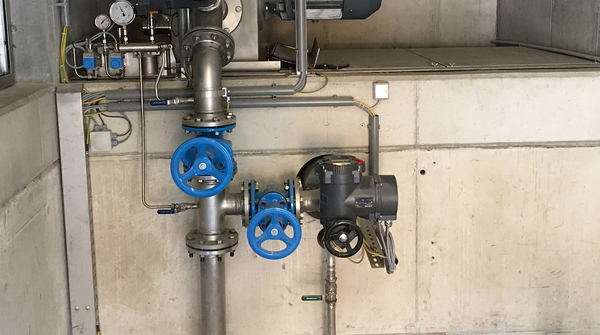

Rehabilitation measures for the elevated tanks II Grün, III Perler, IV Greider, V Tal:

- New coating applied to the water chambers with wet spray mortar suitable for drinking water

- Replacement of the entire plant construction in stainless steel

- Renewal of the entire electronic I&C technology including control system/remote monitoring

- Hermetic seal between valve and water chambers by means of insulating glass

- Forced ventilation of the water chambers

- Sealing and thermal insulation of the elevated tanks

Technical data for power plants:

- Turbine type: Pelton

- Generator: Asynchronous

- Minimum water flow rate: 22 l/s

- Total line length: 5,280 m

- Total gross drop height: 700 m

- Total power plant output: 133 kW

- Total annual power generation capacity: 1,110 MWh/year